My Vespa notes - placed online for anyone else that might need a bit of info on fixing up their Vespa Sprint 150's. I'm no expert so let me know if you see any issues ;)

Thursday 31 May 2012

Sunday 27 May 2012

The Mysterious 12V Wiring System

Found this online just now - finally a reference to a 12 volt wiring system for a Vespa VLB

Furthur Research is still needed - im slowly tracing out the wiring but there are a few mysteries to solve ;)

REF: http://scootrs.com/moreinfo.cfm?Product_ID=1465

Also a Forum: http://forum.allaboutcircuits.com/showthread.php?t=8255

Furthur Research is still needed - im slowly tracing out the wiring but there are a few mysteries to solve ;)

Vespa Wiring loom for CDI kit VBB/VBC Super/VLB Sprint

Details

- Stock:

- V1911A-CDI-2

- Weight:

- 320 grams

Description

This wiring kit goes with our 12v VBB/VBC/VLB CDI (electronic ignition) kit using PX-style flywheel and Ducati-type CDI/coil unit, BUT only if you want to rewire the whole scooter. (The electronic ignition kit itself already includes a loom to add-on to your original wiring.) This kit includes:- wiring loom

- modified horn/light switch

- 12v brake switch

- ignition switch with keys

REF: http://scootrs.com/moreinfo.cfm?Product_ID=1465

Also a Forum: http://forum.allaboutcircuits.com/showthread.php?t=8255

Wednesday 23 May 2012

Clutch Cable Replacement - From Scooter Help Website

| ||||||||||||||||||

| ||||||||||||||||||

|  |  |  |  |  | |||||||||||||

|  |  |  |  |  | |||||||||||||

Replacing Cables

General

Vespa Clutch Cables - Non P Series Vespa Gear Cables - Non P Series Front Brake Cable Rear Brake Cable Lambretta Throttle Cable Speedometer Cable Lambretta Choke Cable Vespa Choke Cable - Non P Series Resources Home | ||||||||||||||||||

Gear/ throttle Cable Replacement

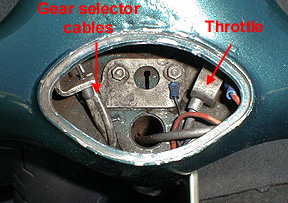

This section shows a quick step by step of replacing cables on an older type (pre P-series) scooter. The first step is to remove the headlight unit with two small screws located at about 4 and 8 o'clock when looking at the headlight. The unit can then be hinged out from the bottom and lifted to release a top pin from the headset. The bulb holder can be disconnected by undoing the two metal clasps that attach it to the headlight.

Remove the speedometer by undoing the center of three bolts when looking at the bottom of the headset. The speedo drive and speedo bulb will also have to be disconnected as you pull the speedometer clear. Once this is done you should see something similar to the picture below.

This sections shows how to replace the inner and outer cables for the gear selector box/ throttle slide assuming that the cables are ready for the trash.

I find it is easiest to simply remove the gear end of the twist grip to get the ends of the cables out at the headset end. Using a 10mm socket, remove the central bolt.

Once the pulley is removed, save the spring washer and locating washer that remain on the twist grip end for the rebuild. Move the cables so that the little "top hat" ends to the outer cable disengage from their supports as shown above. Pull the cable inner out of the outer with a pair of pliers. Once it is out you can clip the head of the outer cable to get rid of the crimped metal end as this could get caught as you pull it through the frame.

If you are just removing the inner cable then replace the top hat over the cable outer end, lubricate the new control cable inner with oil, and then thread the new inner in to the existing outer cable all the way until you see it at the selector box end.

If you are also replacing the outer cable you can clip the head of the outer cable to get rid of the crimped metal end as this could get caught as you pull it through the frame as shown in the next few shots.

| ||||||||||||||||||

Sunday 20 May 2012

Clutch Cables Forum - may pertain later

|

Hi everyone, so the first few weeks of owning this little beast have been amazing but not trouble free.

First a broken cable for downshifts from 4-3-2-1 so I was stuck in 4th gear, thankfully very close to home. Took it to the shop and since I negotiated a 6 month warranty they fixed it. Second my front brake was almost non-existent and every time I shifted into first gear the horn gave it a little "beeep". Highly embarassing but OK Third, last night while riding I noticed it was hard to shift through gears so I called the shop and they told me to adjust the clutch cable by the engine but when I looked at the cable by the handle I realized that I am on my last two threads. I will take it back to the shop so that they replace the cable but I'm worried that it will happen again. It's puzzling because I never had an issue with the clutch cable on my 1978 P125X. Is this a common issue and is there a permanent cure? Thanks and I love reading this forum! |

||

|

if your cable is wearing up by the lever it

is either that is has no lube or never been lubed, and or the adjuster

has a burr it it and is wear/cutting the cable. ensure the cable is not

run to create over binding it should have enough to be flexible from the

lever down the the body. no tension. when you get the new cable a

little squirt once a month of some white silicone grease at the barrell

going into the lever should help for premature wear.

|

||

|

Hi Mate, It not a common issue

When you replace your cable make sure to grease the whole cable with white lithium grease (Panef) Or better. Make sure you a getting good cables too there is a lot of shite on the market. Your clutch cable should have a fat nipple or nipple insert on it. Keep away from crap cables. I have been using bicycle cables for clutch, gears for years. *Be sure it's routed correctly (Nipple sitting flush in your lever) Also check for the two wave washers that fit either side of your lever. If you are in the US or Canada i can call you and talk you through it 10 mins or less and done Cheers |

||

|

Replace both the inner and outer cable.

Unlike the throttle and shift cables (they have a separate nipple that the outer cable's metal bushing fits into), the clutch is comprised only of the outer's metal bushing that presses against the metal in the headset. Eventually that bushing compresses (especially if the clutch adjustment is too tight) and will start to split. That will rub the inner cable and cause it to fail prematurely. HTHs \osc | ||

Pictures of the Red & White 1967 Vespa with the sides off

Electrical

Well this will be a work in progress - the books show a good diagram unfortunately that has very little to do with how my bike is wired so for a start a few pictures of parts - my plan is to clean this up over the next few days

|

| Toyota Relay 12v 90987-02006 / 056700-6912 Denso |

|

| General Wiring on Battery Side |

|

| Can't seem to find the replacement for these if anyone knows where to find them please let me know |

| |

| KT Flasher 10w x 2 + 1.7 W Relay |

|

| 12 Volt 1.5 Amp Trickle charger & Canadian Tire 9-BS Eliminator Battery |

Subscribe to:

Posts (Atom)